CONTENTS

• Planning and Construction | Wake Forest Rd Paving & Hardscapes

• Planning and Construction | Winston Hall Window Replacement

• Planning and Construction | Scales – Brendle Recital Hall

• Planning and Construction | Kentner Stadium Turf Replacement

• Planning and Construction | Allegacy Federal Credit Union Stadium

• Planning and Construction | Reynolda Hall “The Pit” Ceiling Refresh Design

• Planning and Construction | McCreary Football Complex

• Planning and Construction | Worrell Hot Water Boiler Replacement

• Planning and Construction | Academic Classrooms

• Planning and Construction | Graylyn Pool

• In-House Construction | Reynolda Gardens Production Greenhouse

• Planning and Construction | Space Information

• 2023 Facilities and Campus Services Projects

• Environmental Health & Safety

• Custodial

• Landscaping

• Athletic Field Maintenance

• Waste Reduction & Recycling

• Fleet Services

• Maintenance and Utilities Teams

• Lockshop

• Fire & Life Safety

• Warehouse

• Work Order Statistics

• Events

• Energy

• Team Building

• Social Media Engagement

Planning and Construction | Wake Forest Rd Paving & Hardscapes

The project replaced the surface course of asphalt, replaced the curb and gutter, restriped the lanes, and replaced most of the sidewalks. The sidewalks to the North of Sutton Center remained, as they were replaced in 2016 when the gymnasium was renovated. The concrete sidewalks were extended to six feet wide along Wake Forest Road, except in a few locations where existing landscaping and grading did not permit. This project also included the right-hand turn lane from Wake Forest Road at the Shuttle Hub intersection that was deferred from the Summer 2022 project due to timing and underground conflicts with dry utilities. The project began after May commencement and was completed in August 2023.

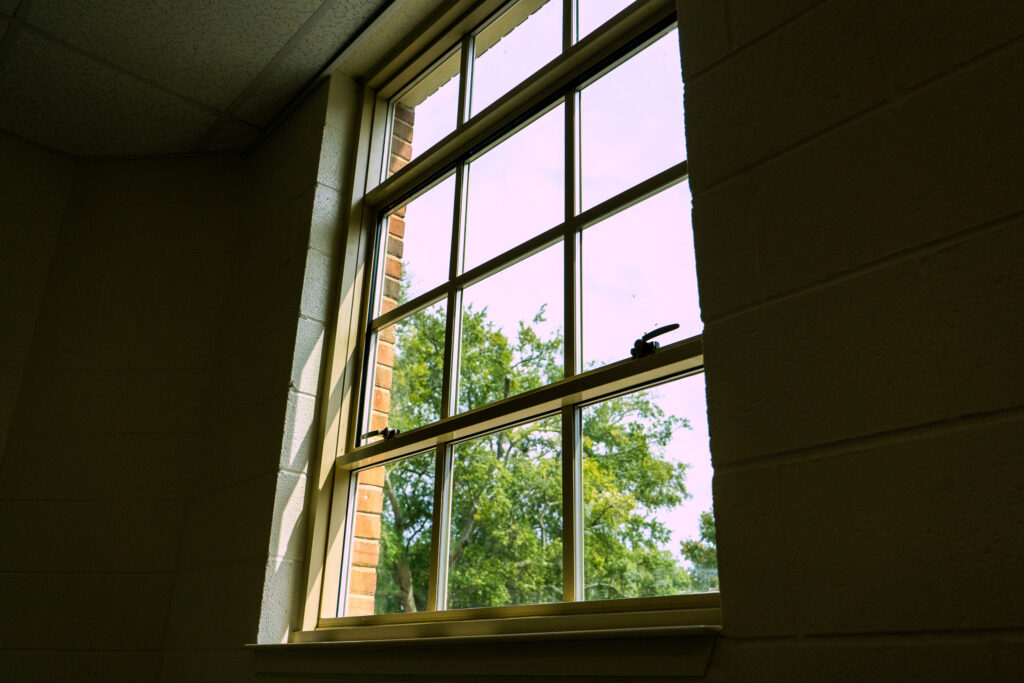

Planning and Construction | Winston Hall Window Replacement

This project was dedicated to the replacement of 137 aging exterior windows in Winston Hall. The primary objective was to swap out the existing inefficient exterior metal single-pane windows with newer, more energy-efficient alternatives (excluding 1990 addition). These upgraded windows not only contribute to the overall improvement of Winston Hall but also align with sustainable practices, reducing energy consumption and promoting a more environmentally friendly and cost-effective building environment.

Planning and Construction | Scales – Brendle Recital Hall

The renovation encompassed enhancing the aesthetics of the recital hall, incorporating soundproofing measures, and replacing the auditorium seating, which had reached the end of its useful life. This comprehensive effort not only improved the physical environment but also elevated the overall functionality and appeal of Brendle Recital Hall for the entire university community.

Planning and Construction | Kentner Stadium Turf Replacement

The Kentner Stadium Turf Replacement project marks a milestone in enhancing athletic facilities at Wake Forest University. The upgraded turf now offers improved drainage and consistent playability, benefiting ROTC, Club Sports, and Field Hockey programs. The implementation of inlaid lines reduces maintenance efforts while ensuring precision and durability. Moreover, the incorporation of new WFU branding, logo, and colors adds a unified identity to the stadium, fostering pride and belonging among athletes and spectators.

The second phase of this project focuses on the renewal of Kentner Stadium, starting with turf replacement. Future improvements include track resurfacing, irrigation upgrades, and technology enhancements, all set for the summer of 2024.

Planning and Construction | Allegacy Federal Credit Union Stadium

Covering an expansive 95,238 square feet new turf was installed in Allegacy Stadium. New handrails were installed on both the East and West sides of the stadium creating improved safety for fans. Within the Deacon Tower, the Athletic Director Suite was reconfigured and refreshed. Out on Deacon Hill, new stairs were added that flank the scoreboard and create new connections from the concourse to the field. All new LED lights were installed to replace the previous three hundred and twenty-eight (328) 1,500-watt Metal Halide light fixtures. These LED lighting products meet the ESPN Venue Guide Broadcast Light Level requirements, enhancing the enjoyment of spectators and ensuring the safety of the participants.

The project also made updates in Bridger Field House, creating a new section for coaches within the home locker room and refreshing the carpet and paint throughout.

Planning and Construction | Reynolda Hall “The Pit” Ceiling Refresh Design

This project scope included renovating to renovate the ceiling components in “The Pit” within Reynolda Hall, which provides for improved aesthetic enhancements and continuing with a long-range improvement plan originally established in 2016 for this popular dining venue.

Planning and Construction | McCreary Football Complex

Located adjacent to the field house and Sutton Sports Performance Center, this new football facility offers players convenient access and hosts essential amenities within its 60,000-square-foot space for comfort and performance. This new space includes the players’ lounge with ping-pong and pool tables, large television screens, an equipment room, a nutrition station, and an athletic training area. Players can rejuvenate in hot or cold pool areas after a nap. A multipurpose room accommodates 200 individuals for team meals and meetings, while 130 lockers offer ample storage.

Planning and Construction | Worrell Hot Water Boiler Replacement

The replacement of the end-of-life Worrell Boilers with Hot Water boilers brought forth several significant benefits to the Worrell Professional Center and Alumni Hall. The installation of new condensing hot water boilers yielded a notable efficiency gain. This enhanced efficiency translates into reduced energy consumption, lower carbon emissions, and decreased operating costs, contributing to a more sustainable and cost-effective operation. Furthermore, the upgrade ensures improved reliability in the heating system, enhancing overall performance and minimizing downtime. Additionally, the project involved the renewal of aging underground piping, addressing potential issues, and ensuring a more robust and reliable heating infrastructure for the long term. Overall, the replacement initiative not only modernizes the heating system but also aligns with environmental and economic objectives, fostering a more efficient and resilient energy solution.

Planning and Construction | Academic Classrooms

In our ongoing mission to renew and enhance the academic experience for students and faculty, the University has undertaken a classroom refresh initiative. This encompasses upgrading various facets crucial to a learning environment, including writing surfaces, AV equipment, ceilings, carpets, paint, furniture, lighting, and window shades. In 2023 ten classrooms were fully renovated completing phase one of a multi-year renovation plan.

Planning and Construction | Graylyn Pool

The primary goal of this project was to resurface the inside of the pool after many years of wear and tear had eroded the surface to the point where it began to chip and leak a significant amount of water. The new surface is designed to last 20-25 years and will be a significant improvement to this historic pool. In addition to the resurfacing several improvements were made to the pool’s bathhouse. Lighting was updated to new energy-efficient LEDs which are also much brighter. The showers received new fixtures, a new ceiling grid, and a fresh coat of paint throughout the locker rooms. The pool pump was upgraded and insulation was added to all water pipes in the building to minimize the risk of future breakdowns and increase efficiency.

In-House Construction | Reynolda Gardens Production Greenhouse

Back in fall of 2023 Reynolda Gardens had gotten the all clear the the renovation of the historic Lord and Burnham greenhouse would begin in late October. While tremendously exciting, this also posed a challenge in that the Gardens did not have a space to relocate the orchids and plants from the collection that were being saved. The Gadens would also be losing production space that is used to grow plants for plant sales, a critical component of earned revenue for the gardens.

Gardens director, Jon Roethling, had sourced a 24′ x 72′ greenhouse frame and necessary components (heaters, fans, vents, etc) but lacked the bandwidth or expertise within the Gardens team to assemble this kit and bring functionality to it. Thankfully the WFU Construction team stepped in and, despite this being the first greenhouse project they had undertaken successfully got the greenhouse assembled and operational just in time for plants to be moved out of the historic greenhouse in order for demolition to begin.

Having this new production house is an asset beyond just housing the orchids and other plants during construction. Having this new production space once the restored Lord & Burnham reopens allows the Gardens to lean more into the vision going forward of the historic greenhouse being focused on display rather than production space. This actually results in a net gain in production space which will result in more production capacity and hopefully a corresponding increase in revenue from plant sales.

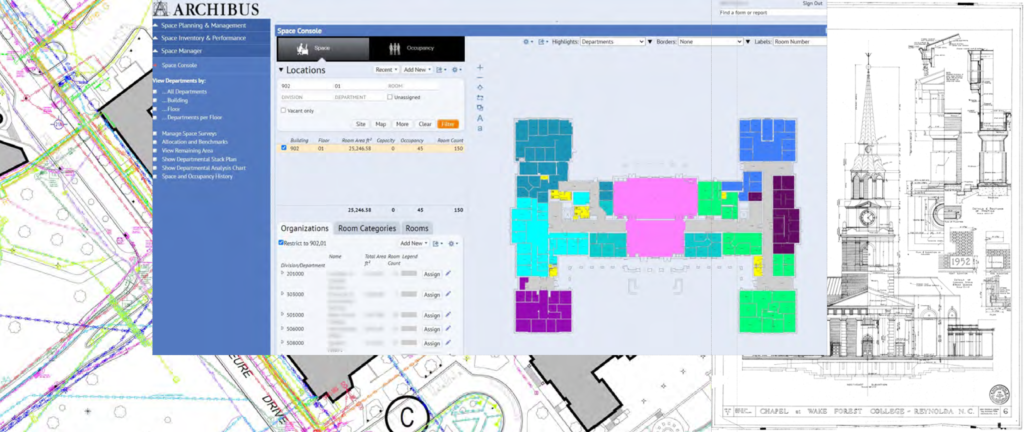

Planning and Construction | Space Information

The Space Information department maintains the University’s system of record (Archibus) for space data. This data is a combination of building plans (CAD files) linked to a database where the data can be presented in tables, charts and graphs in different formats and styles. In addition to the space database we also maintain the University’s Utilities Plan. This is a dynamic digital file that is constantly updated and shared with campus partners and external consultants. We also house and update the Univerisity’s building plan archives, which can be anything from current CAD drawings to original building plans (paper and digital formats).

2023 Facilities and Campus Services Projects

Operations Projects

Planning and Construction Projects

Alumni Hall generator renewal – New generator at Alumni Hall

Bridger Fieldhouse LED lights – Replace lights in the lobbies of Bridger with LED lights

Collins – Install GPS units on all fan coils and replace shower valves (men’s & women’s restrooms)

Farrell Hall Carpet Upgrades – New carpet in various classrooms

Greene Hall– Install 5 electronic keybads for doors in Psychology department

HS Moore Complex Exterior Paint – Soft washing and painting exterior of buildings, minor repairs to exterior metal siding and signage

Kirby – Replace (2) sets of exterior doors on McPherson Road side

The Pit – Cap (2) steam lines in Pit that are no longer in use, Replace freezer condensor and evaporators

Kitchin – Common spaces

LJVM Panic Devices – Install (8) panic devices on east side lobby doors

Deacon Place Trim Painting & Caulking – Prep and paint trim and recaulk the buildings

Allen Easley additional outside lights – Additional LED lighting along Allen Easley near WF road

NCA Medium Voltage Conversion – Connecting NCA 1 – 10 to campus MV electrical distribution system

NCA Exterior Softwash/Painting – Painting all metal/columns on 4 buildings/softwashing buildings

Reynolds Gym Restroom Fixtures – Replace (14) low flow urinals

ROTC interior updates – new carpet and paint in various areas of the ROTC Building

Scales Split System – Replace split system in MH207, carpet in the Scales Lobby

Tribble C203/C211/C201 carpet/paint – New carpet and paint

West Chiller Plant equipment removal – Removed old chillers and cooling towers

Worrell light changeout – replace fluorescent lights with LED. Approx 150 lights

XC Trail rehab – Cut back vegetation, repair washout areas, regrade with additional stone/screenings

ZSR Library – Replace (3) water fountains with bottle filler stations

**In collaboration with our campus partners

Babcock Residence Hall – Common spaces A/V upgrades & exterior envelope repairs

Chick-fil-A – First floor painting & flooring, Equipment Refresh

Carswell Hall – Refresh of 2nd floor restrooms. Carswell Hall 019 paint/flooring/window treatment/ceiling/lighting/furniture/writing surface and A/V.

Greene Hall – Refresh of 4th floor restrooms

Huffman Colonnade repair – Repair of colonnade- bluestone/granite, addition of a ramp.

Kentner Field Turf – Replacement of artificial turf at Kentner Field

Kirby Hall – Refresh of furniture in atrium for student study space. B01B | BO3 | BO4, Renovation of (2) classrooms into (1) larger classroom,

Long Drive Lighting/Callbox – Install lighting and call boxes along Long Road and around Deacon Place

The Pit – Ceiling refresh – Refresh of the Pit ceiling – new ceiling tiles/accents, new lighting

Scales – Various classrooms window caulking, , seating, carpets, paint, lighting, acoustical panels, paint/ceiling/writing surfaces/window treatment/furniture and A/V

Tribble – Refresh of Tribble C-wing basement offices, replacing doors and door frames.

Wake Forest Road – Hardscape/Paving upgrades Wake Forest Road – Shuttle Hub to University Pkwy

Winston Hall windows – Window replacement Winston Hall (excluding 1990 addition), Refresh multiple classrooms -paint/flooring/ceiling,Renovate interior finishes and new lab casework, AV upgrade

ZSR Elevator – Elevator replacement – Reynolds Wing main entrance elevator,Renovation of circulation desk area,Interior finishes upgrade and new furniture,

Environmental Health & Safety

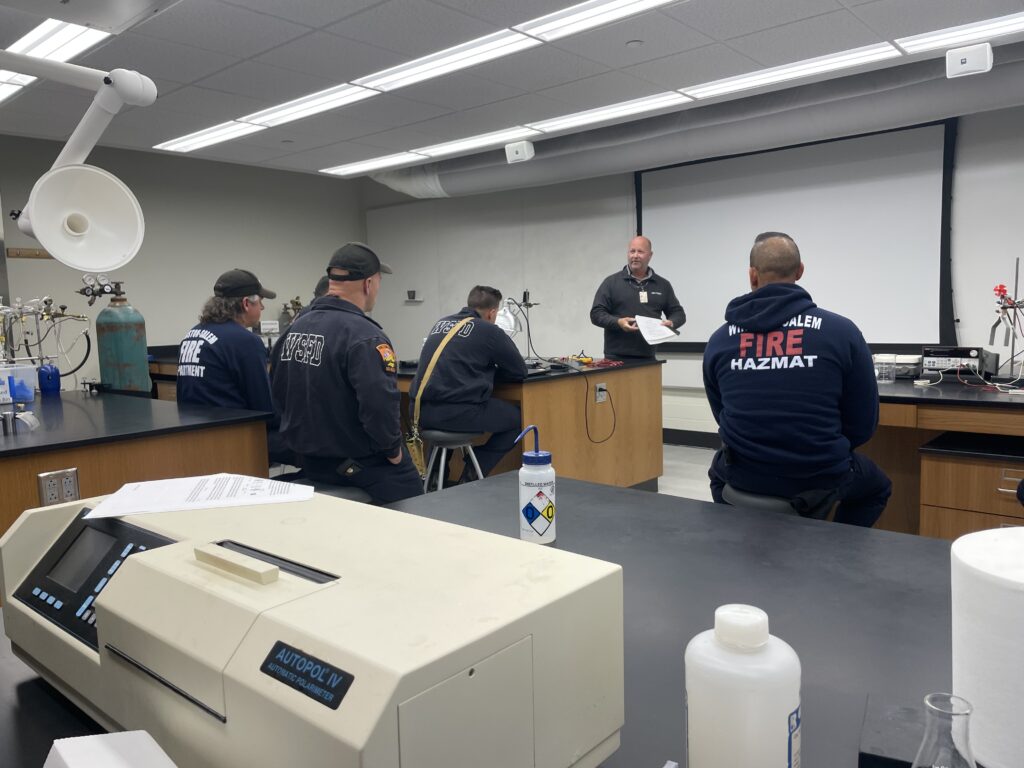

Incident Response Training with WSFD

EHS hosts an annual training session for the Winston Salem/Forsyth County hazmat team. The team is presented with real-world scenarios they may face in a University environment. This year, the chemical and physical hazards in Salem Hall were reviewed, followed by a simulated laboratory chemical release event.

Hazardous Waste

Many chemical products may be considered regulated hazardous wastes at the time of disposal. Hazardous wastes pose a significant threat to human health and the environment if handled incorrectly, and are strictly regulated by the Environmental Protection Agency (EPA).

F&CS Office of Environmental Health and Safety (EHS) is responsible for the collection, storage and shipping of hazardous wastes generated during University operations, teaching and research. EHS also provides training for Wake Forest University individuals who generate hazardous waste.

Much of the hazardous waste generated at the University comes from teaching and research labs and from art studios. Waste oil and paints are generated by Facilities and Campus Service.

Most hazardous waste can be categorized in one of the following categories:

| Flammable | Corrosive | Reactive | Toxic |

| Solvents from research labs. | Acid etching bath from Art. | Lithium batteries from all campuses. | Lacquer based paint from F&CS. |

Laboratories and art studios are provided collection containers for waste. EHS collects these waste containers on a regular basis and consolidates like kinds of waste in designated hazardous waste accumulation areas on Reynolda Campus and at Wake Downtown.

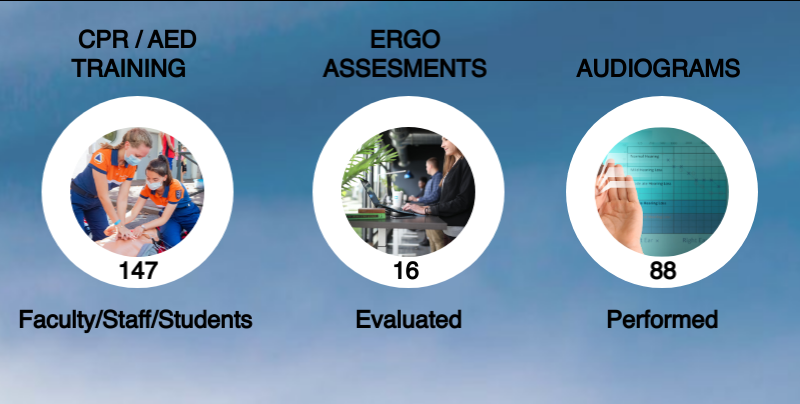

CPR / AED Awareness

Wake Forest University is committed to maintaining the safety and well-being of all students, faculty, staff, and visitors on campus. The office of Environmental, Health, and Safety (EHS), Wake EMS, and the AED Committee partner in the promotion of a robust Public Access Defibrillation (PAD) program, which includes Automated External Defibrillators (AEDs).

Since 2013, the University’s PAD program has grown exponentially. There are now more than 100 units scattered across Reynolda Campus & our off-campus properties and an additional 30+ units within our Athletic facilities. A 3-year replacement plan for all units is in place. Year one will address all remaining Phillips HeartStart units at some of our off-campus locations and the oldest Cardiac Science units that were initially placed in 2013. Subsequent years will see an upgrade to the most current Cardiac Science on the market.

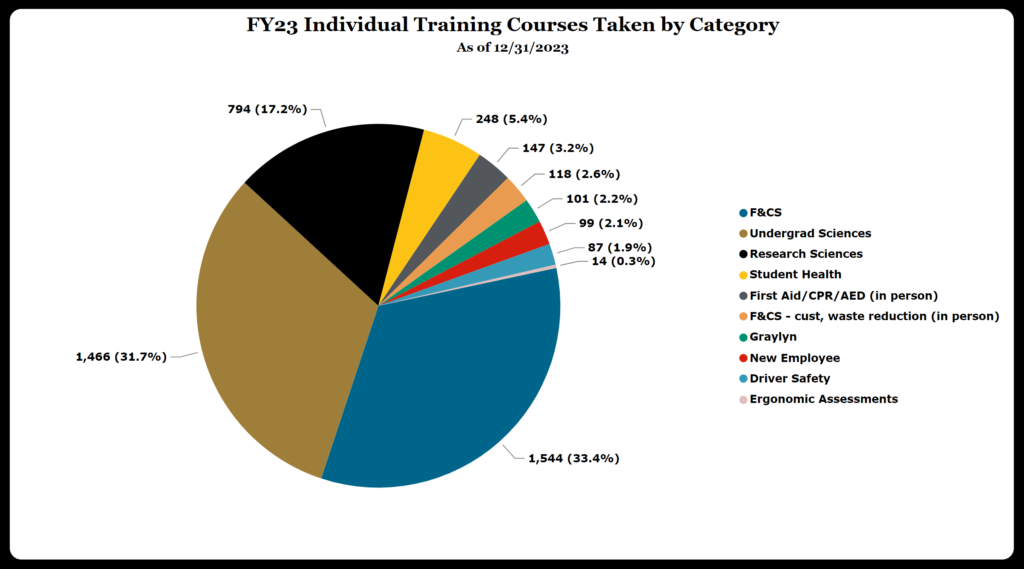

By the Numbers

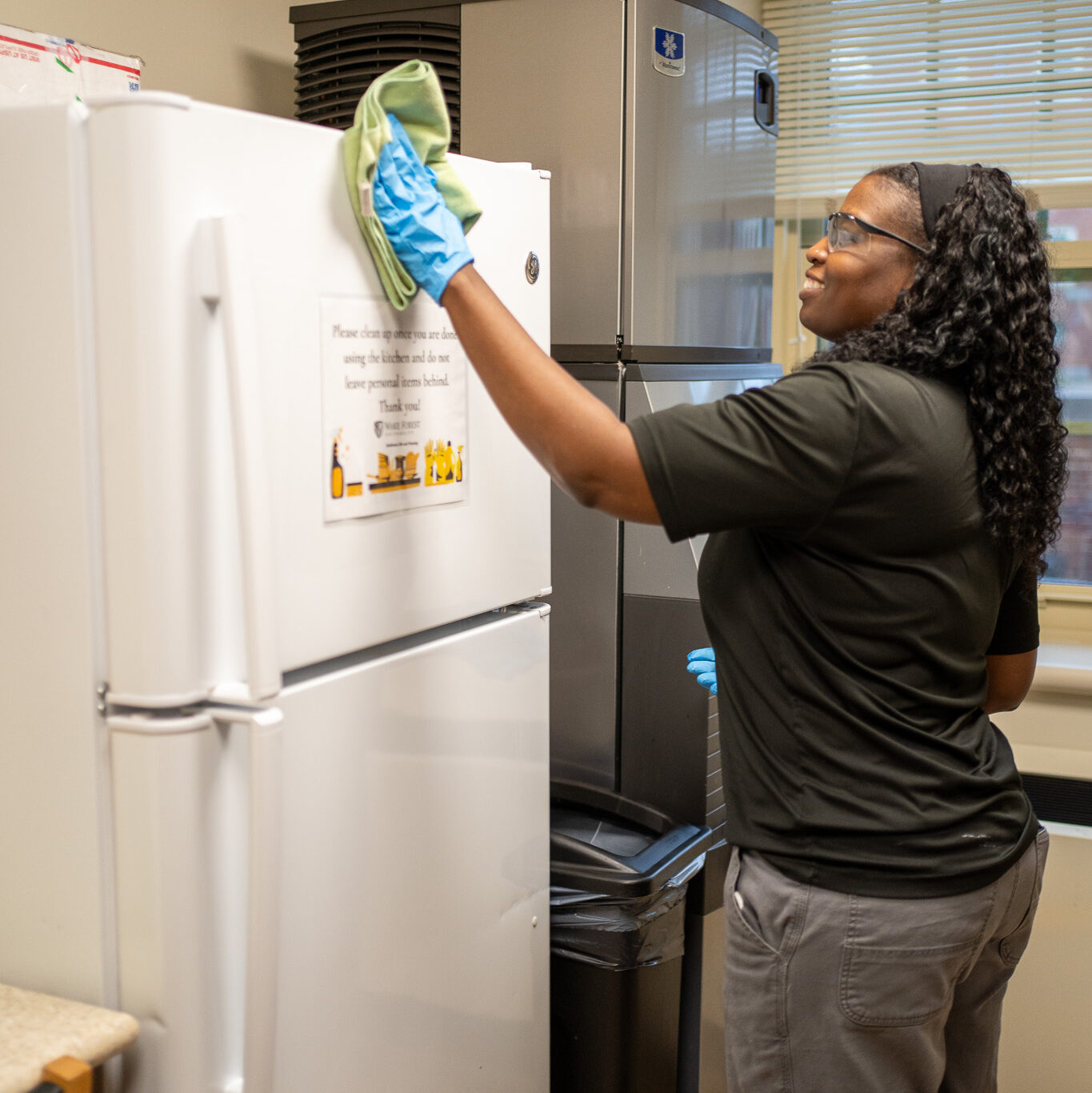

Custodial

By the Numbers

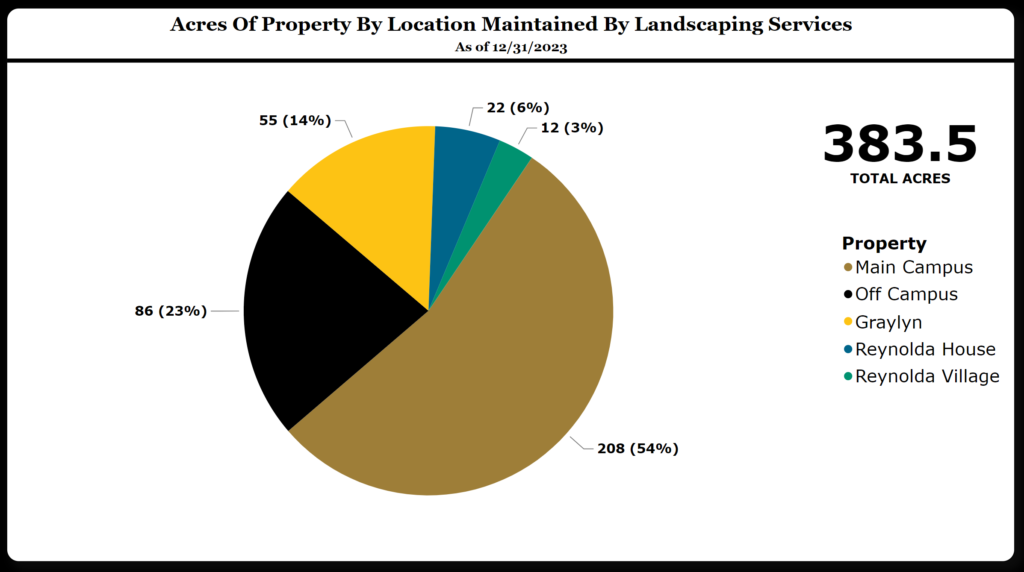

Landscaping

Short video tour with Paul Sheff highlighting some of Wake Forest University’s landscaping

Exploring the Rooted Connection: Unveiling the Distinction Between Native and Non-Native Plants. Paul Sheff delves into the intriguing parallels between flora and humanity, sparking thought-provoking inquiries in Z. Carter Berry’s biology class.

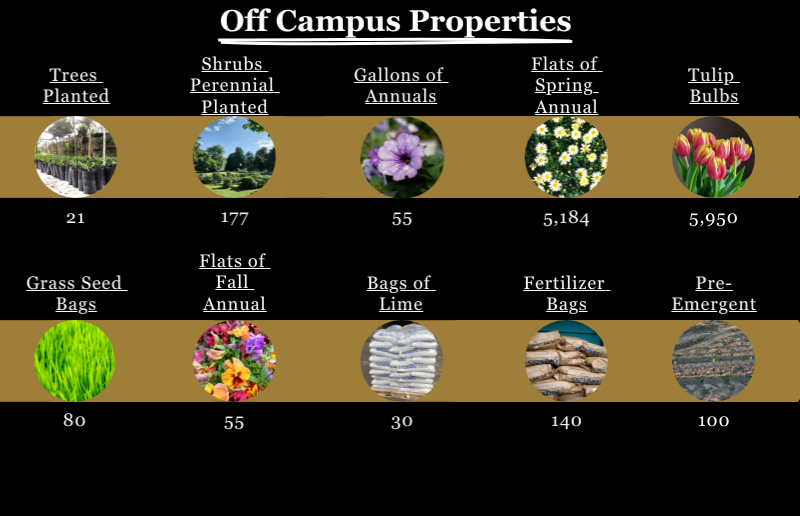

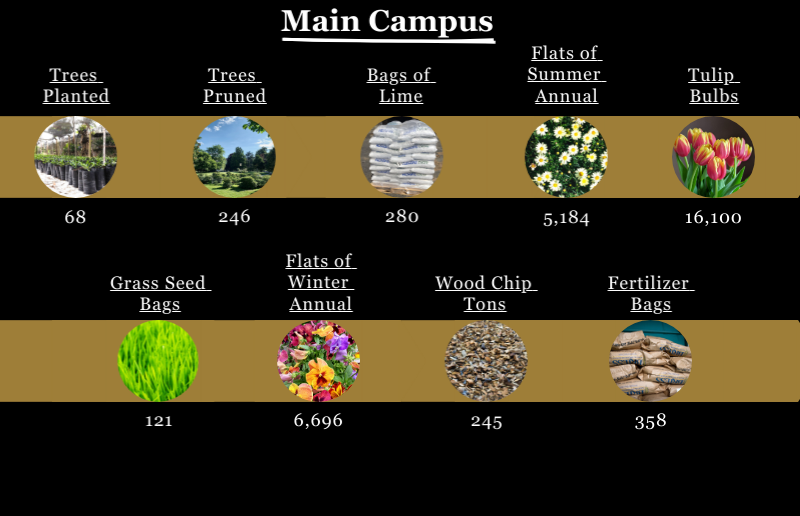

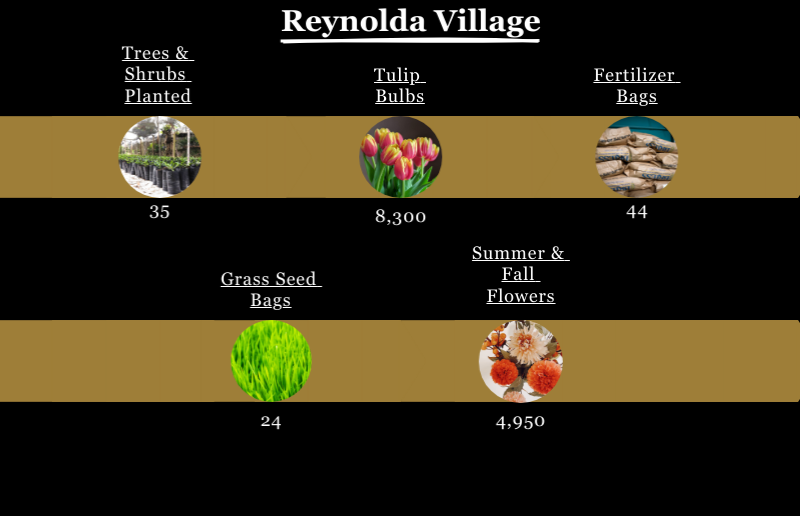

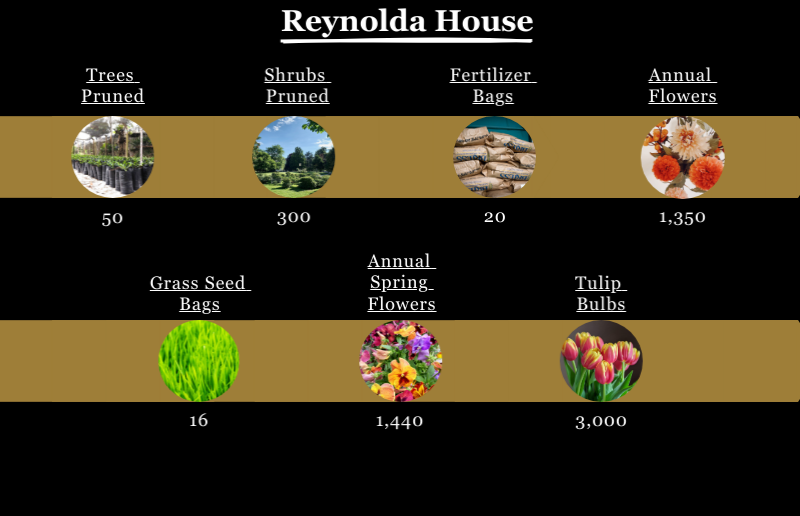

By the Numbers

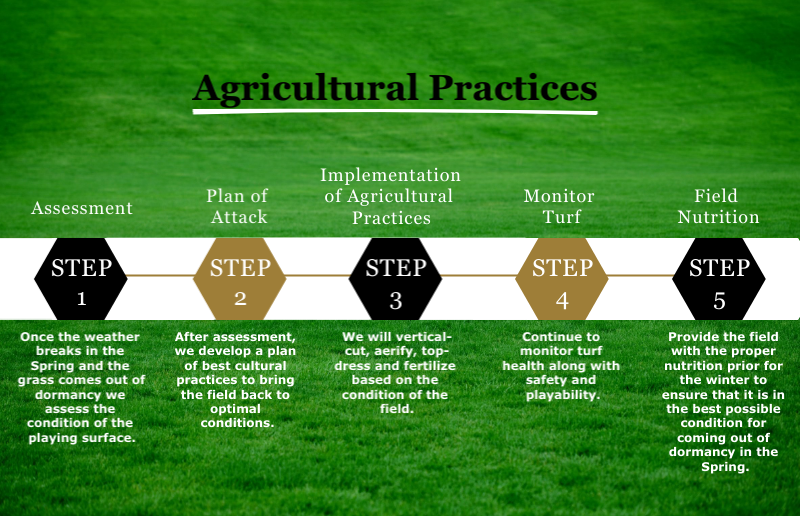

Athletic Field Maintenance

By the Numbers

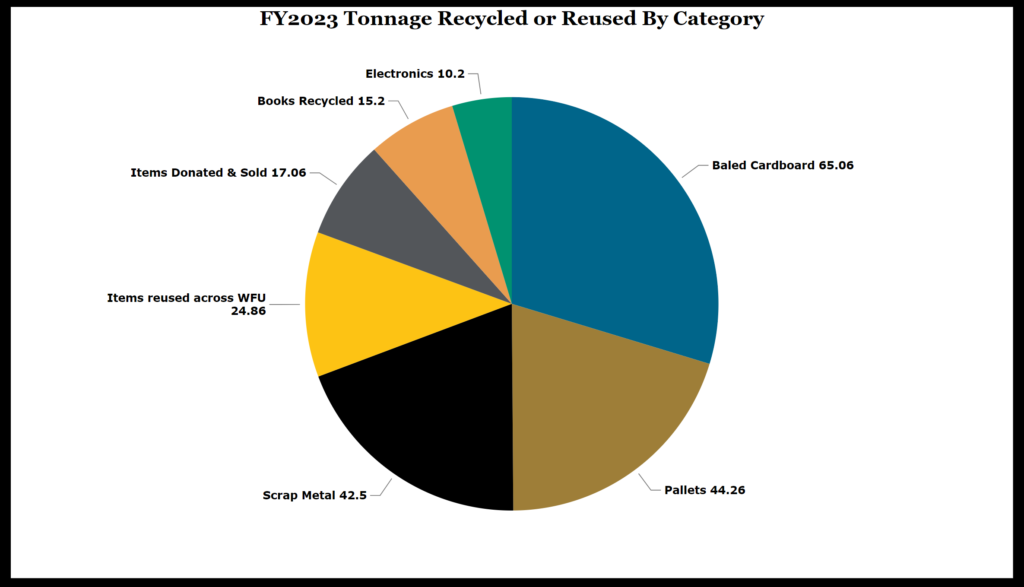

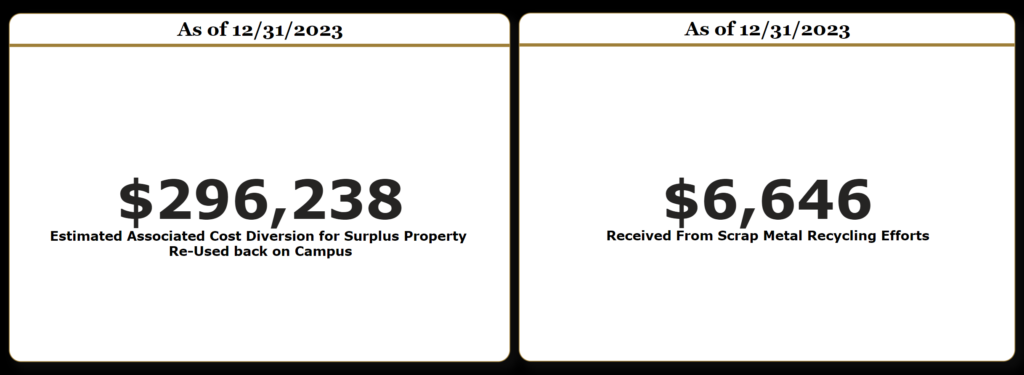

Waste Reduction & Recycling

The 2023 ISUZU Pac Mac 8 Yard is a visually impressive truck that catches the eye as it navigates across the campus. With its high visibility and the inclusion of cameras, it ensures a safer experience for both the driver and those around it. Additionally, its fuel efficiency sets a new standard, contributing to reduced emissions and lower fuel costs.

The “Put Waste in its Place” sticker prominently displayed on the side further enhances visibility and awareness on campus, reinforcing responsible waste management practices.

By the Numbers

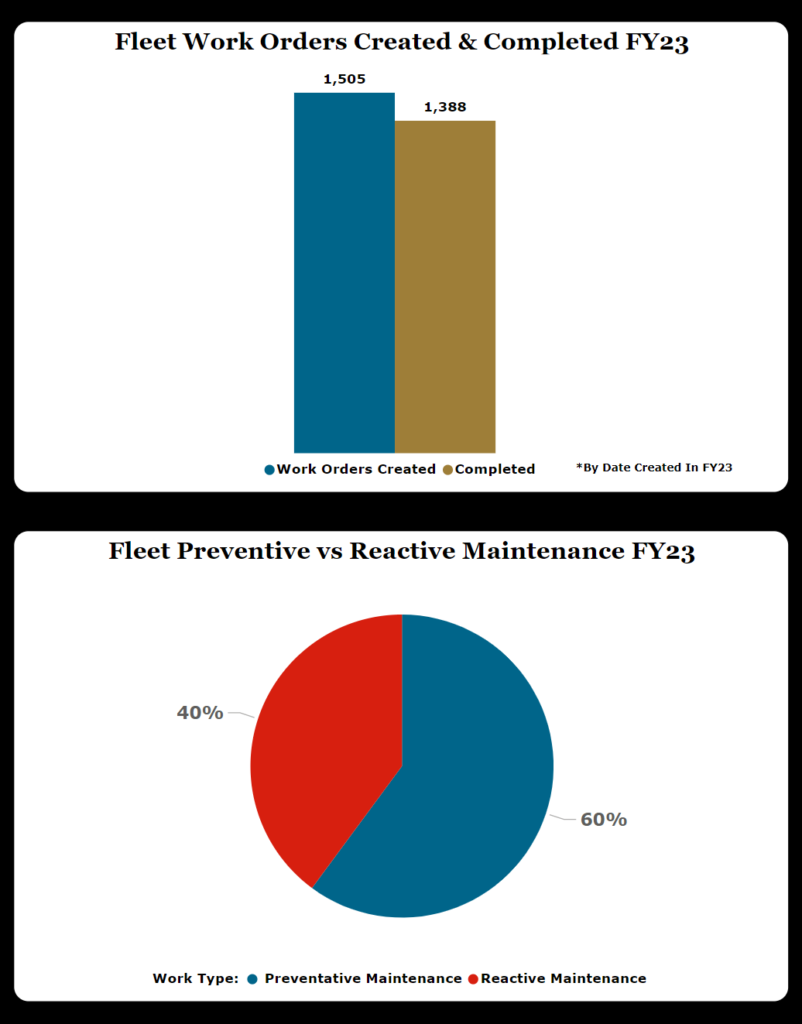

Fleet Services

By the Numbers

Maintenance and Utilities Teams

By the Numbers

Lockshop

The presence of 43 keyboxes across Wake Forest University’s campus, with an additional four installed in 2023, is vital for ensuring safety and security. By securely storing keys within these boxes, the risk of misplacement or unauthorized access is reduced, ultimately safeguarding the campus environment and its occupants.

By the Numbers

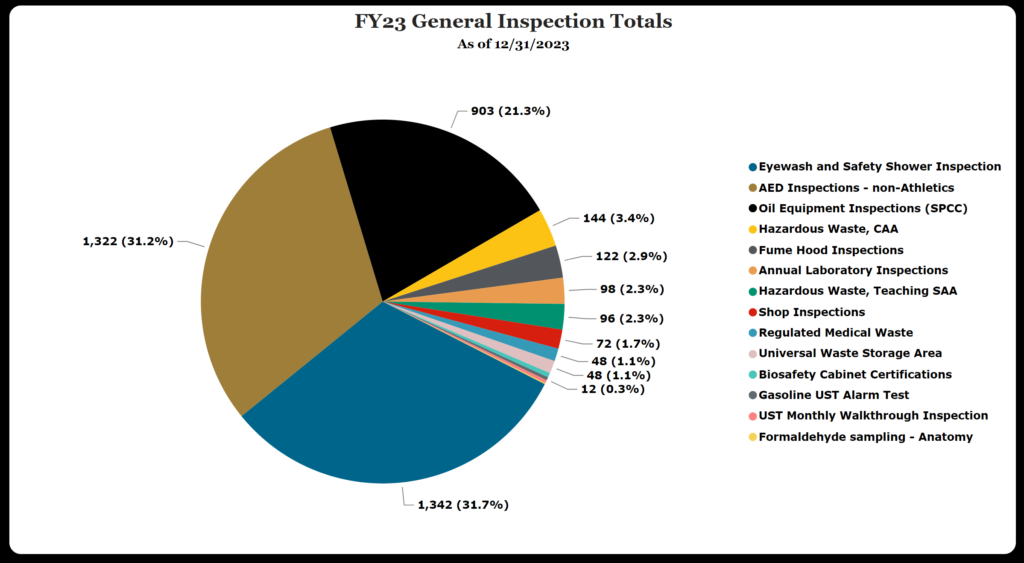

Fire & Life Safety

The Wake Forest University Fire & Safety team consists of Manager Scott Frazier and Rob Hager with a combined University service of over 40 years. Together they manage Campus fire systems including fire panels, hydrants, extinguishers, and fire drills. Throughout the year they ensure our safety by performing multiple inspections and scheduled tasks while maintaining professional and courteous stewardship of our facilities.

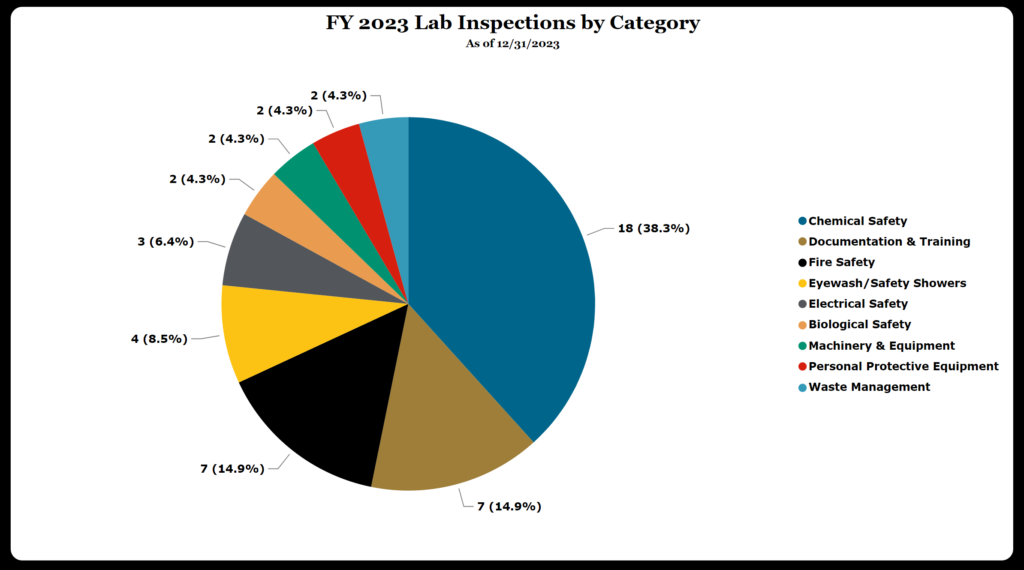

By the Numbers

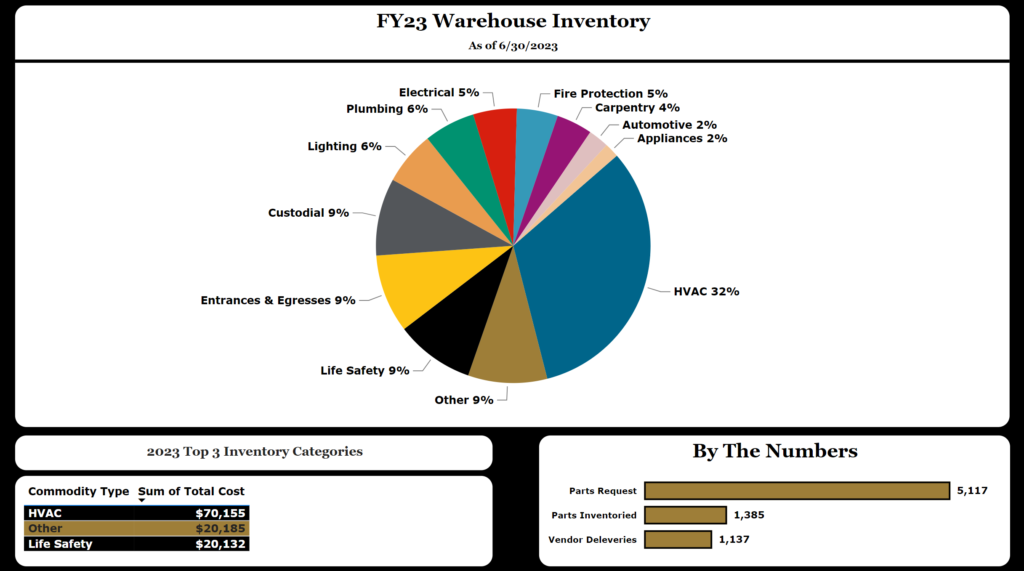

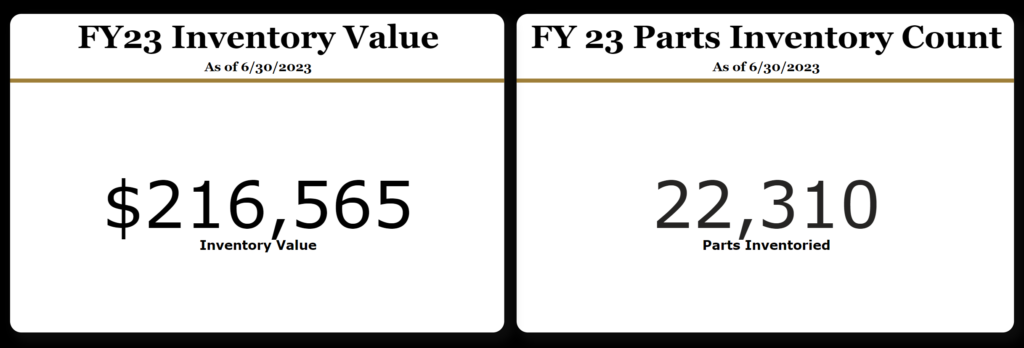

Warehouse

By the Numbers

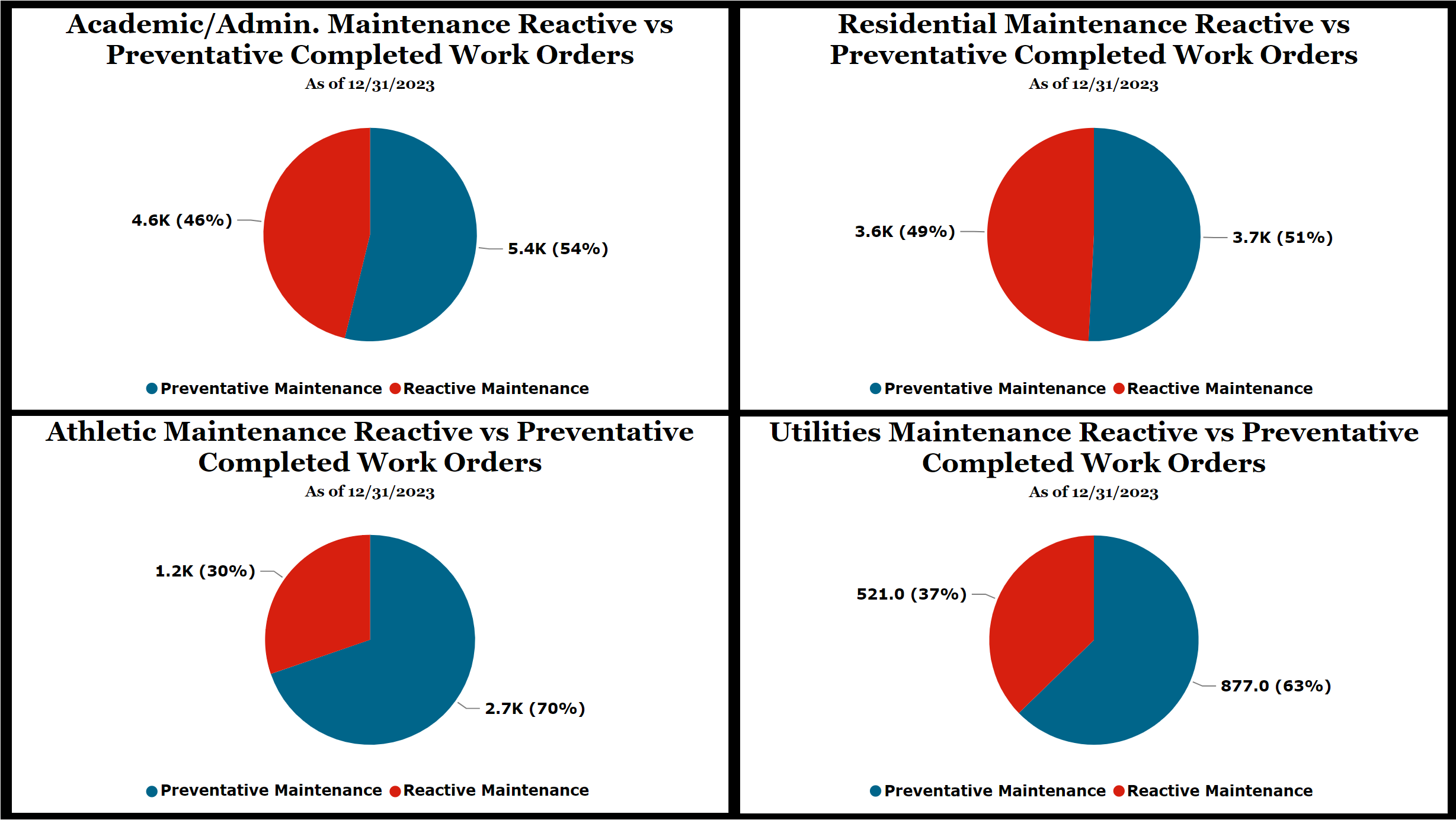

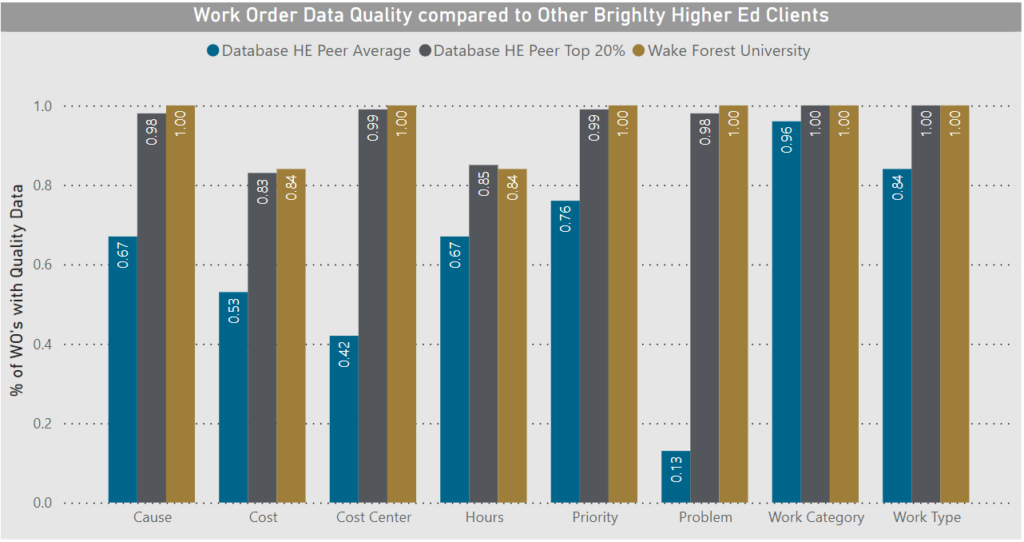

Work Order Statistics

By the Numbers

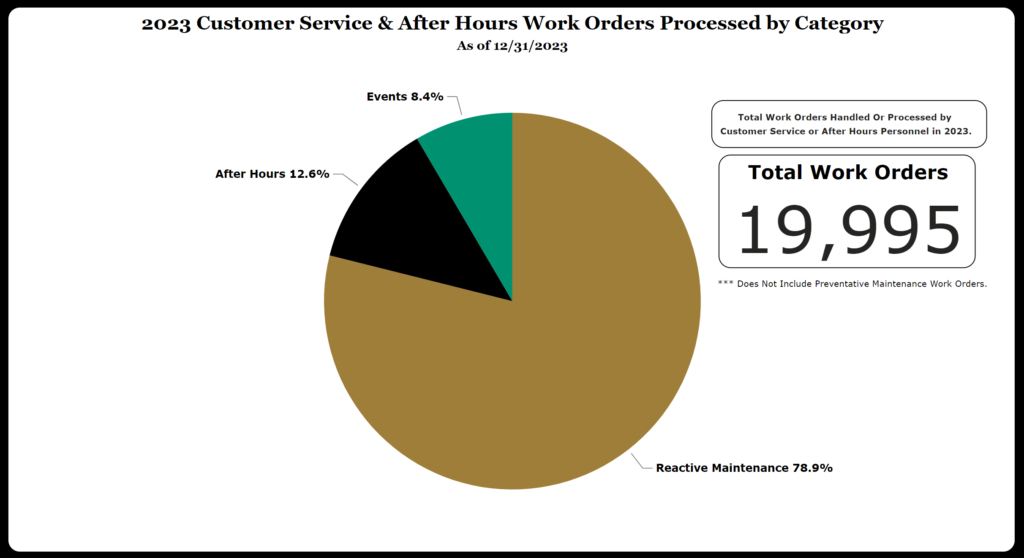

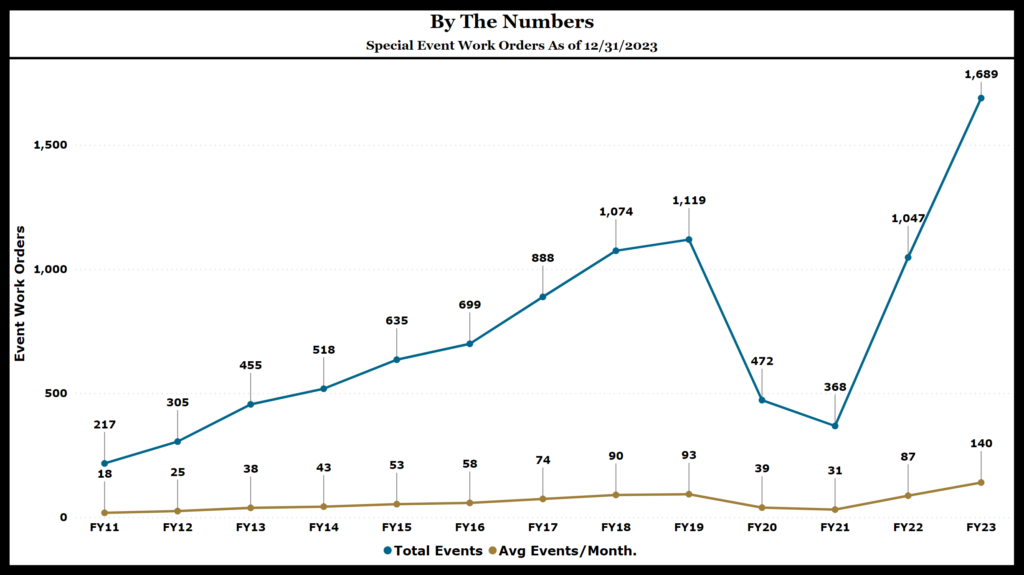

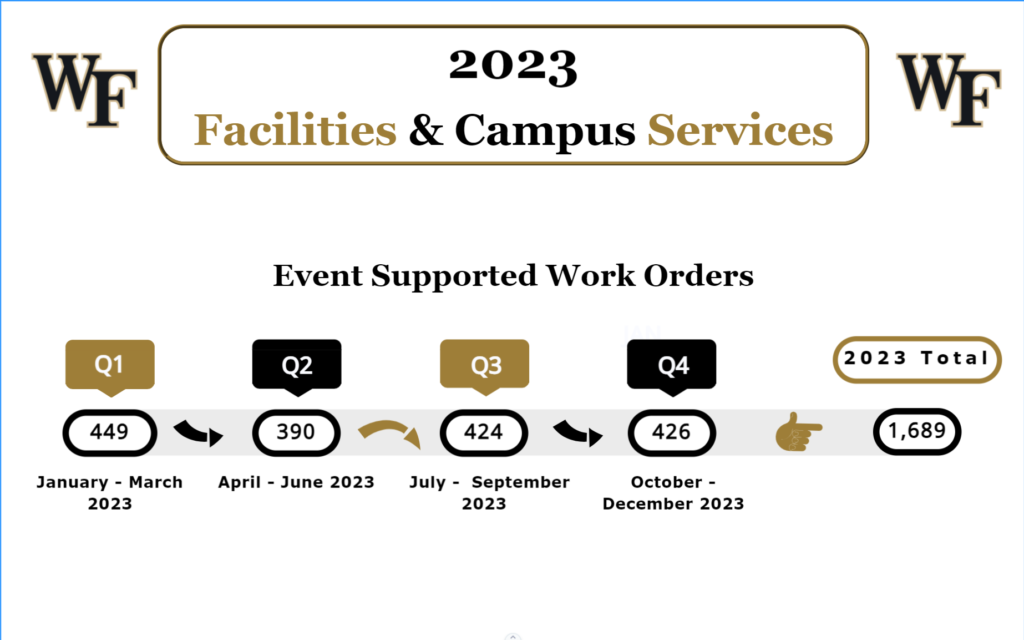

Events

By the Numbers

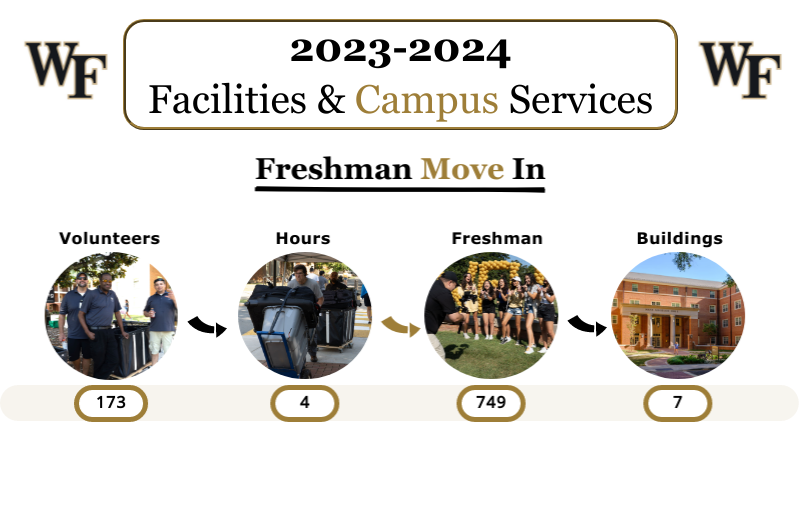

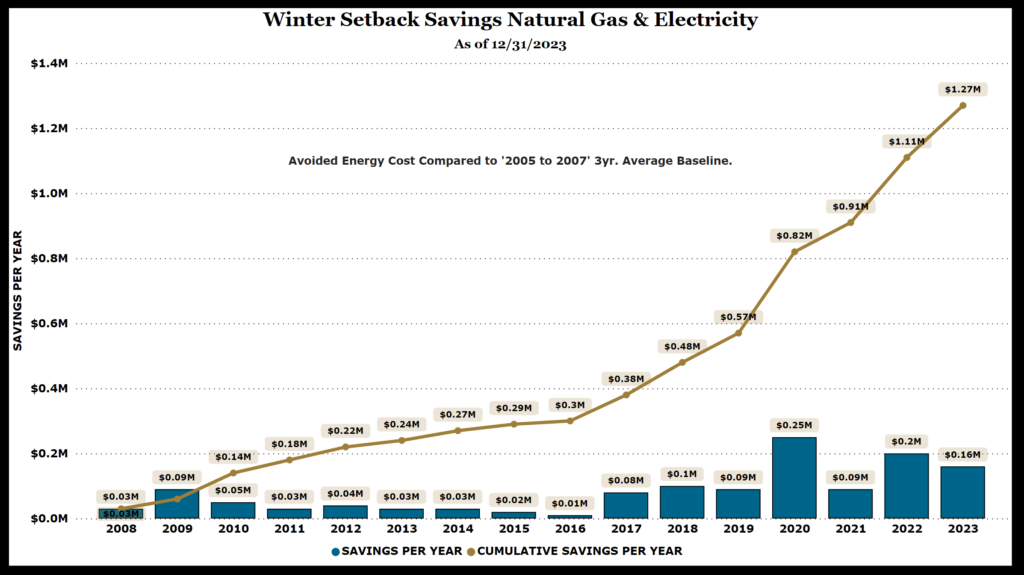

Energy

By the Numbers

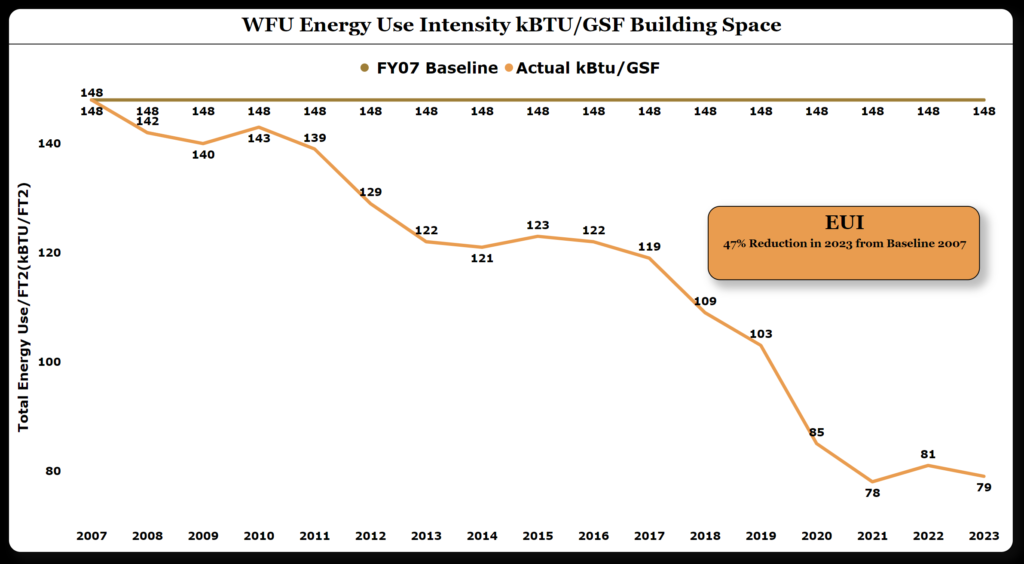

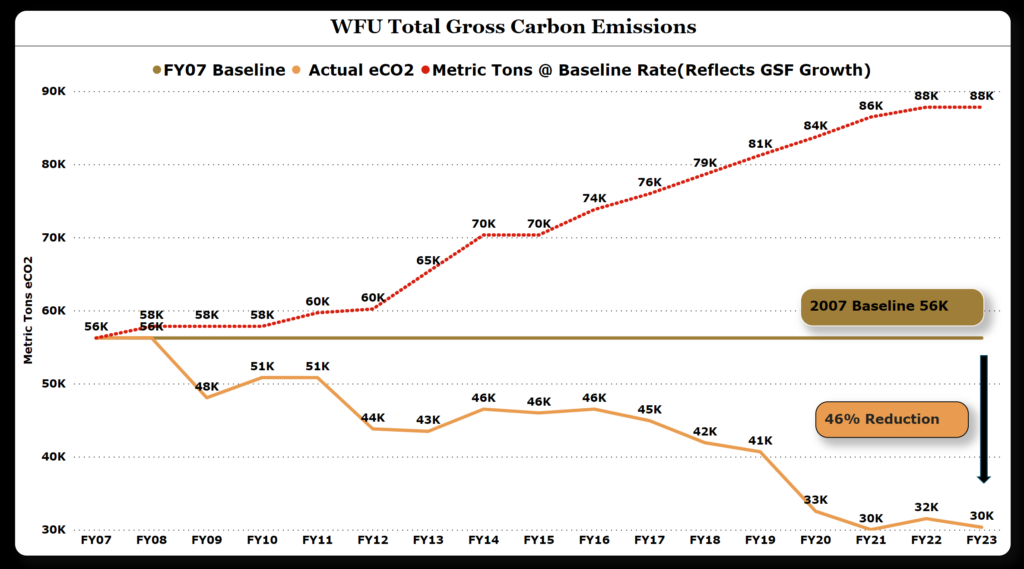

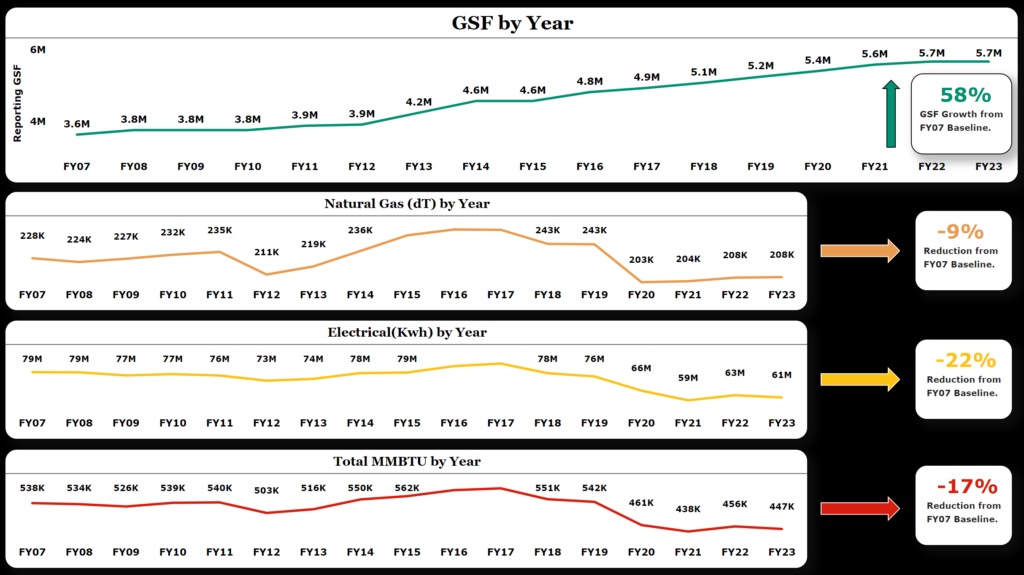

Reynolda Main Campus is responsible for approximately 68% of total WFU annual carbon emissions and energy usage. Through continuous energy conservation and efficiency efforts, WFU collaboratively achieved a 79 kBtu/GSF or 47% reduction in energy use intensity. This energy usage reduction combined with a cleaner utility grid has resulted in a 46% reduction of gross carbon emissions from our 2007 baseline of 148 kBtu/GSF and 56,229 eCO2 Metric Tons.

Our gross carbon emissions have been reduced by over 46%. The emissions graph represents what our gross carbon emissions would have been if we were to continue at our FY07 baseline rate per GSF of emissions.

The University has added 58% or 2.1M GSF to our Energy / Carbon Footprint since 2007 but reduced overall energy use by 17%. We have been champions of energy reduction and continue to improve upon best practices and maximize energy efficiency.

Team Building

Social Media Engagement

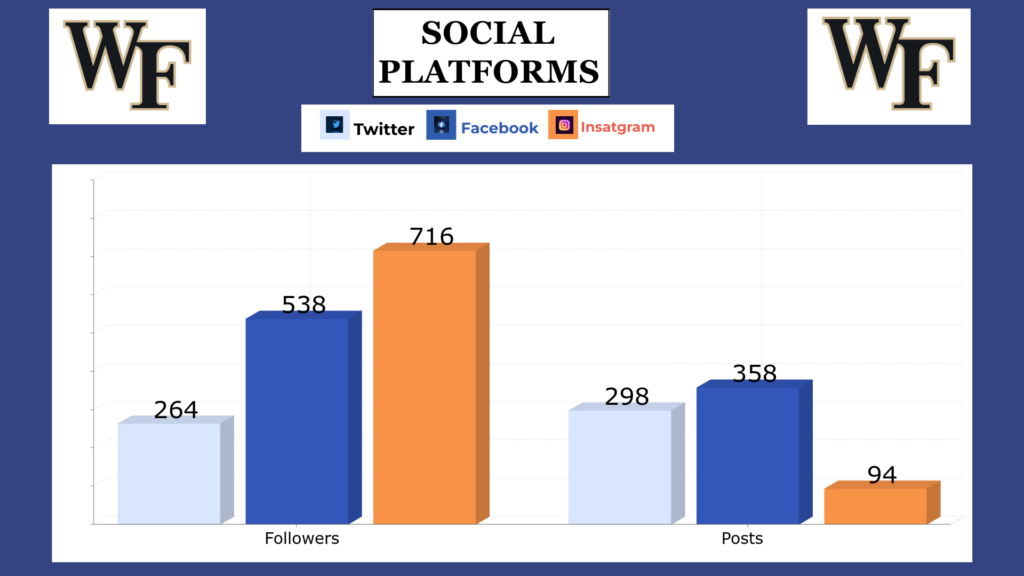

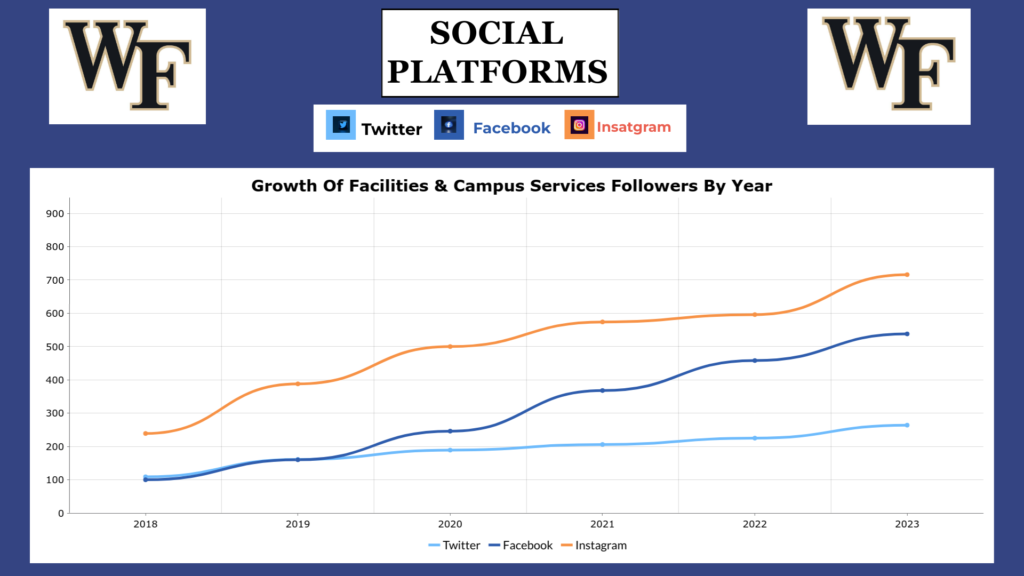

By the Numbers